A folder gluer is a machine used in the packaging industry to fold and glue cardboard into various types of packaging such as boxes, cartons, and other folded products.

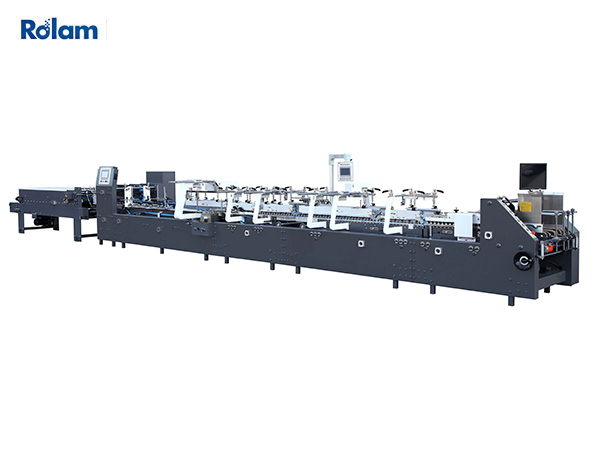

Folder Gluer Structure

A typical folder gluer machine consists of several key components including a feeder, folding section, gluing section, compression section, and delivery section. The feeder is responsible for feeding the sheets of cardboard or paperboard into the machine. The folding section then folds the sheets into the desired shape and size. The gluing section applies adhesive to the appropriate areas of the folded sheets. The compression section presses the glued areas together to ensure a strong bond. Finally, the delivery section collects the finished products and stacks them for further processing or packaging.

Folder Gluer Machine Working Principle

The working principle of a folder gluer involves a series of precise movements and processes to fold and glue the sheets of cardboard or paperboard.

First, the sheets are fed into the machine and guided through the folding section where they are folded into the desired shape and size.

The gluing section then applies adhesive to the appropriate areas of the folded sheets.

The sheets are then compressed together to ensure a strong bond between the glued areas.

Finally, the finished products are collected and stacked in the delivery section for further processing or packaging.

Summarize:

the folder gluer machine plays a crucial role in the packaging industry by efficiently folding and gluing cardboard or paperboard sheets to create various types of packaging products. Its precise movements and processes ensure high-quality finished products that meet the requirements of customers and industry standards.