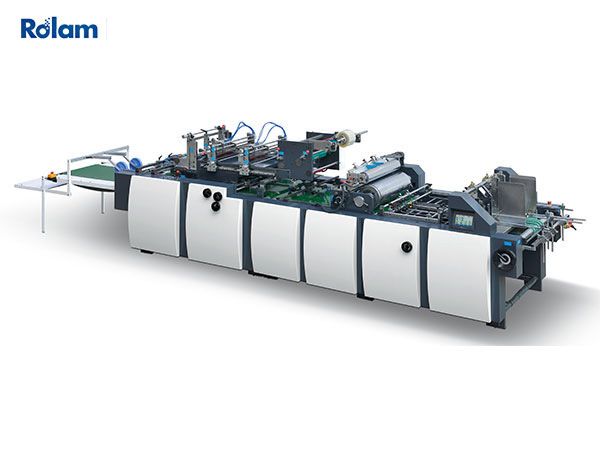

The window patching machine is to stick a layer of film on the open window of the unglued window carton, using the patented suction belt type paper feeding mechanism, smooth and reliable paper feeding; chain pushing and grasping type paper positioning, positioning and turning; synchronous automatic gluing; length can be adjusted automatically into the film, film cutting, film sticking, etc. The whole machine includes five major parts: paper feeding part, positioning part, glue printing part, film sticking part and paper collecting part. During the production process, it is possible to adjust the front and back position of the paper, the left and right position of the glue and the left and right position of the film without stopping, the adjustment of the first three is very convenient and quick, and it is very simple, convenient and fast when changing products. Details are as follows

Paper feed section

The paper feeding part adopts the downward drawing type paper walking, the paper walking is even and stable, the paper can be added continuously without stopping, the intermittent belt conveying adopts electric eye tracking, frequency control, according to the paper length can adjust the intermittent conveying length, the conveyor belt can be adjusted left and right.

Automatic window sticker positioning section

The positioning section adopts double chain hooks to push the paper, plus two sides against the paper, so that its position is accurate and stable. The position of the chain hook can be moved left, right, forward and backward, and the front and rear adjustment of the double rows is adjusted by adjusters, without stopping to adjust the paper and film lamination position, and the double electric eyes control the paper empty sheet and continuous sheet.

Printing and gluing section

The upper glue section adopts the lower suction belt transmission, so that the paper does not run, and the large roller is attached to the mould, which has a greater range of action. With the reference line, the mould can be installed faster and more accurately. The moulds can be moved forward, backward, left and right to flexibly adjust the position of the glue printing, strip rubber moulds, simple, fast and beautiful splicing. Round roller with nylon plate type glue storage, more glue saving and easier to clean.

Laminating section

Adopting infinitely variable speed device, the length of the film can be adjusted with partial stop; adopting roller knife to automatically cut the length of the film, automatically slitting the opening of the motor (e.g. tissue box); adopting suction tube roller to suck and stick the film onto the carton, the front and back position of the film can be adjusted with partial stop.

Receiving section

Belt conveyor for stacking and collecting paper, which is neat and easy to collect.