Introduction of the machine

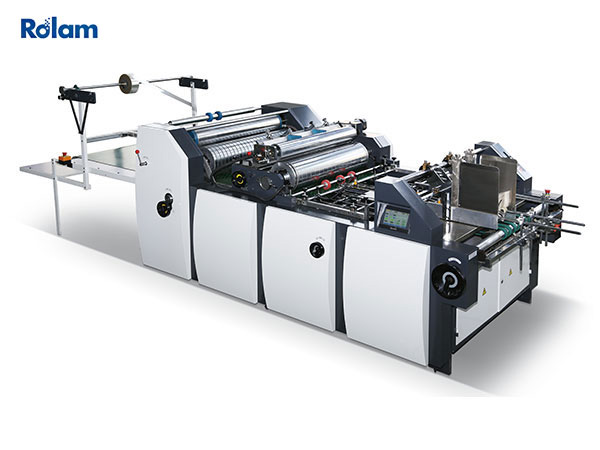

GK-1080T Window Patching Machine is widely used in the film patching to be package with or without the window of the wine box .gift box. napkin box. cosmetic box etc. It can also realize the function of the paper gluing ,film patching ,film cutting and paper collection before folding boxes.

The machine has passed the ISO9001 Quality System Certificate and conform the European CE safety standard.

The choose able structure: Window with intermittent slit

1080T Parameters

| Specification of the machine | |

| Model | GK-1080T |

| Max. Paper Size(mm) | 1080*650 |

| Min. Paper Size(mm) | 140*140 |

| Max. Film Size(mm) | 410*300 |

| Min. Film Size(mm) | 80*60 |

| Film Thickness(mm) | 0.05-0.20 |

| Max. Working Speed | 8000-10000s/h |

| Cardboard | 200-500g/m2 |

| Corrugated Paper | ≤7mm |

| Total Power | 9kw |

| Total Weight | 3000kg |

| Overall Dimensions(mm) | 5000*1960*1750 |

| (When the roller pull out) | 5000*3160*1750 |

| Packaging dimensions (m) | 3.1*2.1*2.2m |

| Container | 20GP |

| Net weight (kg) | 4000kg |

| Gross weight (kg) | 5000kg |

1080T Features introduction

|

|

Paper Feeding Section The paper feeder parts is controller by the servo motor, the paper pile make Perfect for the cardboard and corrugated |

|

|

Conveying Section Double paper servo control The paper conveying parts installed the four conveying chains with the four pushing blocks, |

|

Gluing Section The gluing parts adopt the adjustable parts gluing structure , |

|

|

Film cutting Section The upper roller is the film cutting roller with the two blade , The below roller is the suction roller ,the film is patched on the suction roller |

|

|

Paper collection section The patching products conveying to the paper delivery plate, |

|