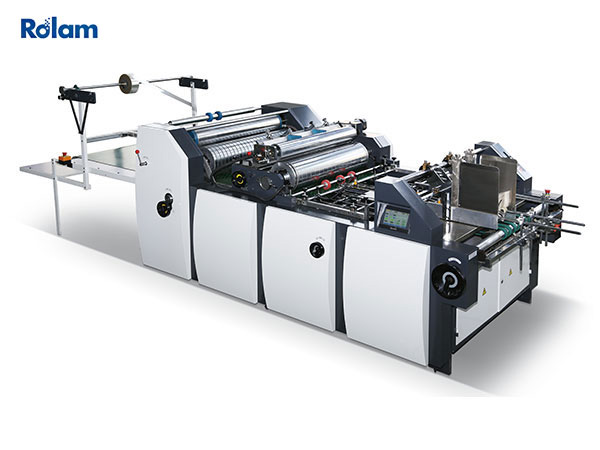

QH Series heavy duty folder gluer is suitable for 4/6 corners/crash lock bottom/staight-line type carton gluing folding. Each section is driven by servo motors and liner guide adjustment,which make machine working more smooth and stable comparing with traditional main motor driving and slides adjustment.With separate unit for secondary-creasing,OH meet 3ply and 5ply cartons folding requirement perfectly.Secondary-Creasing can align the fish tail of cartons due to different reasons sush as improper die cutting and creasing,etc.

QH Series Heavy Duty Folder Gluer Foundation Drawing

QH Series Heavy Duty Folder Gluer Technical Parameters

|

QH TECHNICAL PARAMETERS |

|||

|

MODEL |

1700 |

2100 |

2500 |

|

Paper material |

Cardboard 210-800gsm,A/B/E Flute |

||

|

Max.speed |

280m/min |

||

|

Max.thickness of folded box |

12mm |

||

|

Way of folding |

Fold 1 and fold 3 are 180°and 135°,fold 2 and fold 4 are 180° |

||

|

Power supply |

3P 380V 50HZ |

||

|

Blank width |

1700mm |

2100mm |

2500mm |

|

Length x Width x Height |

24x2.9x2.05m |

24x3.3x2.05m |

24x3.7x2.05m |

|

Net Weight |

14.5T |

15.5T |

18T |

|

Total power |

60kw |

60kw |

60kw |

QH Series Heavy Duty Folder Gluer Function

● Apply to corrugated cardboard paper box.

● Strong stainless steal frame, insure machine running stably with high speed.

● Automatic fault diagnosis alarm function,Wireless remote control for easy user operation.

● Machine with PLC control, photocell touch screen for adjusting machine.

● Low-voltage electrical appliances, button switches, transmission parts, timing belts, press belts, bearings, servo motors, inverters, pneumatic components, etc. are all imported products that meet European and American national safety standards

● Side touch screen displays the machine's speed, output, fault alarm, touch screen controls the machine's start/stop, paper feeding clutch, box receiving part's start/stop, parameter setting and other operations.

QH Series Heavy Duty Folder Gluer Product details description

Paper Feeding Section

1.Equipped with air suction function

2.Multi-stage rail to ensure the verticality of pressing board. To ensure that the paper feeding is not skewed,

3.The unique structure keeps more simple and convenient adjustment of pressing board. Push structure make supporting cardboard adjustment more convenient and stable.

4.Baffle on the left and right can be adjusted upper and down to shorten adjusting and carton changing time.

5.Vibration device coordinate with motor which helps machine consecutive and automatic feeding quickly and simply

Crash lock bottom section

Servo motor control, the entire front bottom locking device ensures accurate bottom locking action. The adjustable bottom hook device makes it difficult to cut the flower box, and the operation control is simple and fast. The front bottom fold adds a secondary creasing function to correct the indentation line existing in the corrugated box itself and enhance the smoothness of large corrugated paper output.

Accessories

The crimping line has high positioning accuracy, which can flatten and shape the cardboard to varying degrees, improve the accuracy of the cardboard into cartons, and can provide standardized and continuous paper feeding. It is easy to operate, saves time and effort, and improves production efficiency.

Lower gluing tank

1.Lower gluing tank is large volume.

2.Easy to remove and clean

Folding and closing

1.Equipped with 3 plate type rail device.

2.The upper pressure belt adopts the main drive and cylinder pressure more suitable for different thickness corrugated products.

3.Folding section with servo motors which can adjust the folding section belts speed separately.

Trombone section

1.Independent motor drive can be used to control the adjustable size of the belt.

2.Paper collection adopts cylinder pressure system, easier to adjust pressure, make the box more effectively gluing.

Transmission

1.Pressing and Transmission unit has regulator, patting device, can effectively avoid the “scissors mouth” phenomenon of corrugated products.

2.Pressing and Transmission unit adopts waiting function, when feeding section is in the pause status, it will automatically enable waiting function. If has error in paper collection unit, it will automatically stop the machine work.

4 /6-corner device

Motorized and untimed electronic back folding system with intelligent servo motor technology

QH Series Heavy Duty Folder Gluer Sample box parameters

|

Straight Line Box Way of folding Carton type and size: |

|

|||

|

Model |

1700Type |

2100Type |

2500Type |

|

|

A+B+C+D+E |

520-1700 |

520-2100 |

520-2500 |

|

|

E(Min) |

30 |

30 |

30 |

|

|

E(Max) |

500 |

500 |

500 |

|

|

F |

300-1400 |

300-1400 |

300-1400 |

|

|

G(Max) |

1600 |

1600 |

1600 |

|

|

Crash Lock Bottom Box Way of folding Carton type and size: |

|

|||

|

Model |

1700Type |

2100Type |

2500Type |

|

|

B+C+D+E |

500-1600 |

500-2000 |

500-2400 |

|

|

E(Min) |

30 |

30 |

30 |

|

|

E(Max) |

500 |

500 |

500 |

|

|

F |

300-1400 |

300-1400 |

300-1400 |

|

|

G(Max) |

1600 |

1600 |

1600 |

|

|

H(Min) |

45

|

45

|

45

|

|

|

L |

40-150 |

40-150 |

40-150

|

|

|

4 Corners Box Way of folding |

|

|||

|

Model |

1700Type |

2100Type |

2500Type |

|

|

A+B+C |

340-1600 |

340-2000 |

340-2400 |

|

|

B |

300-1600 |

300-1600 |

300-1600 |

|

|

F |

300-1400 |

300-1400 |

300-1400 |

|

|

G(max) |

1600 |

1600 |

1600 |

|

|

H(min) |

45 |

45 |

45 |

|

|

L |

40-150 |

40-150 |

40-150 |

|

|

6 Corners Box Way of folding |

|

|||

|

Model |

1700Type |

2100Type |

2500Type |

|

|

A+B+C+D+E |

500-1600 |

500-2000 |

500-2400 |

|

|

B(min) |

220 |

220 |

220 |

|

|

C(min) |

45 |

45 |

45 |

|

|

F |

300-1400 |

300-1400 |

300-1400 |

|

|

G(max) |

1600 |

1600 |

1600 |

|

|

H(min) |

45 |

45 |

45 |

|

|

L |

40-150 |

40-150 |

40-150 |

|