The operation process of automatic window patching machine can be summarized as follows.

1, first adjust the paper, 2, again adjust the push gauge, 3, adjust the film, 4, adjust the queue, 5, adjust the glue.

1, adjust the paper: Generally speaking, the window stickers are pull-down paper delivery machine, just like the gluer, the adjustment method is basically the same as the gluer, it should be noted that some machines operate in a different way, the difference is that the window stickers use photoelectric induction out of the paper, the adjustment is relatively simple and convenient, other machines have different adjustment methods according to the design of different manufacturers.

2, again adjust the push gauge: push gauge according to the shape of the paper for front and back adjustment, in the left and right leaning plate with the paper can be pushed into the suction belt in a balanced manner.

3, adjust the length of the film: different factories use different ways to stick the film, window stickers use servo feeding film, more accurate, the length can be adjusted on the touch screen, some machines are stepless transmission, the need to adjust when starting. Then, compare the position of the film and paper window, the window sticker can be adjusted left and right without stopping.

4, adjust the queue: this part of each manufacturer is basically the same, just use two large wheels to line up, adjust the position of the two wheels and paper.

5, adjust the glue: this is to prevent waste, make abrasives, paste on the rollers, and then adjust the front, back and left position, the window sticker machine can also be adjusted without stopping the front, back and left, including the function of automatic glue jumping when empty sheets.

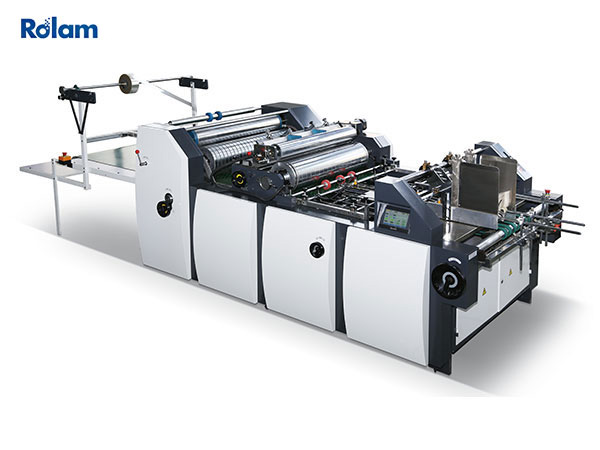

Post-press processing equipment automatic window laminating machine not only continuously improve the speed, and equipment adjustment more concise, humane. Automatic window laminating machine can replace a large number of manual work to complete the window lamination of cartons at one time, and is equipped with environmentally friendly adhesive. The unique structure of the equipment can precisely control the amount of adhesive coating to avoid leakage, fully packaging carton window paste quality and safety. In addition, the equipment also has anti-scratch function, which fully guarantees the finished product rate, and more importantly, the equipment can guarantee extremely high paste precision.