The Importance of Box Folder Gluer Revealed!

The Box Folder Gluer plays a crucial role in the packaging and printing industry. It is not only the final process of box packaging, but also an important part of production automation. With the continuous advancement of technology, the Box Folder Gluer has greatly improved in functionality and performance.

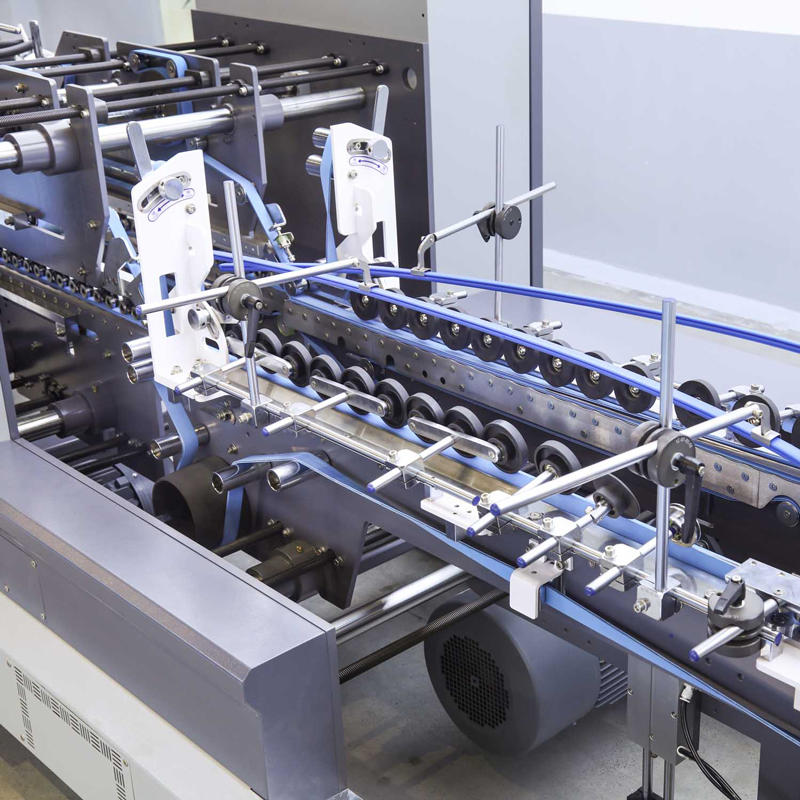

As is well known, the Box Folder Gluer is composed of the paper feeding section, pre-folding section, bottom-locking section, folding section, and pressing section. The automatic paper feeding system of the Box Folder Gluer can quickly and accurately transport the printed cardboard to the next process, avoiding errors in manual operation and ensuring production efficiency. The pre-folding section is also important as it pre-folds the cardboard during the folding process, making the final packaging box more precise and sturdy. The design of the bottom-locking section and forming section ensures the structural stability and neat appearance of the packaging box. The pressing section is responsible for compacting the formed packaging box to ensure its quality and stability.

From a professional perspective, different types of Box Folder Gluers can meet various production needs. Bottom-locking Box Folder Gluers can produce packaging boxes with a bottom-locking structure, reducing the need for manual operation and improving production efficiency. Some high-end Box Folder Gluers can even produce boxes with four or six corners, further enriching the variety and appearance of packaging boxes.

The application of Box Folder Gluers not only improves production efficiency and reduces labor costs in the packaging and printing industry but also provides more possibilities for the design and production of packaging boxes. With the continuous development of technology, it is believed that Box Folder Gluers will play an even more important and diverse role in the future packaging industry.