Although the use of folder gluers has become more and more widespread in recent years, packaging boxes such as food, medicine, pharmaceuticals, cosmetics, alcohol, and light industrial products are processed by folder gluers, but in fact, everyone I don't know much about machines and belts so that I can't deal with them promptly when they break down! Today, Paper box-making machine manufacturer will take everyone to understand together, hoping to deepen everyone's understanding!

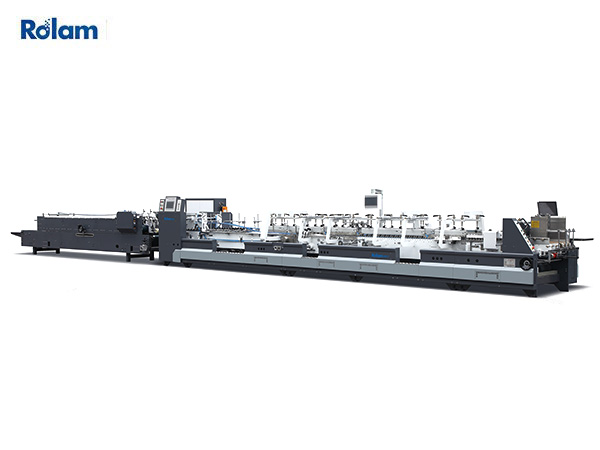

Folder gluer consists of the following parts:

① The paper feeding part is composed of the paper feeding belt, the main front lay, the auxiliary front lay, side fences, paper feeding speed, conveyor belt pressure rollers, and paper stack rear fences.

a. Paper feeding belt. The paper feed belt should be evenly tensioned and tensioned so that the belt cannot slip on the drive shaft. Use as many straps as possible for the size of the boxboard.

b. The main rules. The main front gauge must be on a certain paper feeding belt and then determined according to the carton board. Paper box-making machine manufacturers warmly remind that the position of the main front gauge should abide by the following principles: try to place the main front gauge between the first crease and the third crease; try to make the main front gauge automatically close to the box Middle of the boards; the main front gauge should be placed opposite the longest front board and opposite the widest board as possible.

The height of the main front gauge should be adjusted according to the thickness of the cardboard, and it must be ensured that the cardboard can pass through freely, but there should be no gaps. The presence of double sheets is controlled using an electronic double sheet detection system.

c. Sub-former regulations. The function of the sub-front lay is to further hold the paper stack at the front and prevent the paper stack from falling due to the gap between the side fences. The height of the vice front gauge is generally 3 times the thickness of the cardboard.

d. Side baffles.

When adjusting the side baffles, avoid making the cardboard too crowded between the two side baffles, and generally leave a gap of 1 ~ 2mm.

e. Paper feeding speed. The paper feeding speed of the folder-gluer is adjusted by a continuously variable transmission, please note that the continuously variable transmission cannot be used when the machine is stopped.

f. Conveyor belt pressure wheel. Belt pressure rollers align the board against the side fences to ensure proper positioning of the sides of the board.

g. Stack tailgate. The function of the paper pile rear fence is to make the paper pile slightly inclined for paper feeding.

② The folding part is composed of a folder, an upper conveyor belt, and a non-belt folder.

a. Prefolder. The height of the pre-folding guide plate should be adjusted according to the thickness of the cardboard, and the guide plate should not slow down the speed of the cardboard.

b. Upper conveyor belt. The pressure of the pressure roller guide rail is adjusted according to the cardboard conveying situation, and it is better to adjust it so that the cardboard can be smoothly conveyed without affecting the connecting rod.

The height of the pinch wheel at the cardboard entrance is also adjusted according to the cardboard conveying conditions.

c. Without folder. The Paper box-making machine manufacturer tells you that according to the adjustment according to the thickness of the cardboard, the crease must be folded as required.

③ The gluing part consists of a rubber box and a rubber wheel.

a. Plastic box. The inside of the plastic box is generally coated with a layer of butter for easy cleaning. Butter is a kind of fat with silicon as the main component, and a small amount of use does not affect the composition of the gum.

b. Rubber wheels. Different rubber wheels should be selected according to the strength of the carton.

④ The folding part is composed of a folder and a folding transmission.

a.Folder. The folder should be adjusted accordingly according to the conveying condition of the cardboard and the direction of gluing.

b. Fold the transmission. During the folding phase, the folding gear has a great effect on the alignment of the carton boards. Note that the folding transmission cannot be used when it is stopped.

⑤ Pressurize the pop-up part. The function of the pressurized ejection part is to compact the crease of the folded carton and then accelerate the ejection to the compaction part. It consists of a pressurizing device, an adjustment point, an inlet pressure roller, an outlet pressure roller, and an ejector.

a. Pressurization device. When processing small boxes, only one pressurizing device is required, while when processing large boxes, two pressurizing devices are required.

b. Adjustment point. Each pressing device has a pressure wheel at the entrance and exit, its pressure and height can be adjusted according to the folded carton.

c. Adjustment of the population pinch wheel. It is most conducive to cardboard input when the population pinch wheel is adjusted to a slight pressure.

d. Adjustment of the outlet pressure roller. The exit pinch is adjusted to a higher pressure according to the design of the carton and the desired result.

e. Catapult. Adjust the length of the lower ejectors to follow the contour of the rear of the carton, the carton should exit both lower ejectors at the same time. The upper catapults should always be of equal length.

⑥ Compact the collecting part. The compaction collection part is a mechanically independent device, but the power is still provided by the main motor. There are also some models where the compacted collection part is driven by a separate motor.

The Paper box-making machine manufacturer tells you that the last process of packaging box processing is to fold the printed and die-cut cardboard into shape and glue it to the paste. The machine-glued box replaces the manual box-glued method. Founded in 2006, Zhejiang New Luolan Machinery co., Ltd is a professional equipment manufacturing enterprise integrating R&D, manufacturing, sales, and service. It provides high-quality production equipment for folding cartons, corrugated boxes, and color printing packaging industries. Our customers provide high-quality, high-efficiency, fast, and convenient packaging solutions.