In the modern packaging industry, nail-less boxes and nail boxes are two common types of cartons, and they exhibit significant differences in structure, processing methods, and market demand. This article will analyze these differences from the perspectives of box gluing machine technology and market demand.

1. Structure and Processing Methods

- Nail-less Boxes:

- Structure: Nail-less boxes are bonded together using adhesives (such as hot melt glue), eliminating the need for metal nails, resulting in a cleaner overall appearance.

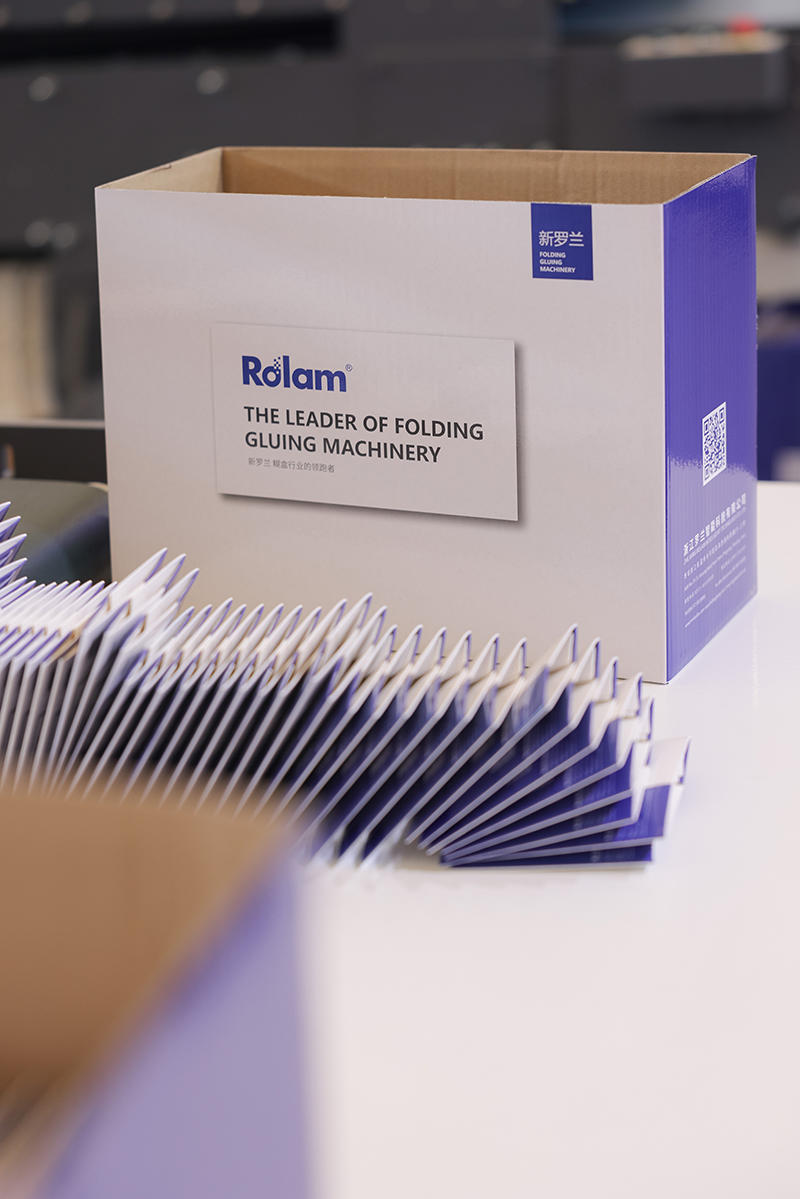

- Processing Methods: They are sealed quickly using box gluing machines, which are specifically designed to ensure uniform glue application, effectively improving production quality and efficiency.

- Nail Boxes:

- Structure: Nail boxes use metal nails for reinforcement, making them generally sturdier and suitable for carrying heavier goods.

- Processing Methods: Traditional box gluing machines only need to complete the gluing process, after which a specialized nailing machine is used for nailing, resulting in multiple processes that lead to a longer production cycle and lower efficiency.

2. Equipment Applicability

The production equipment for nail-less boxes is typically simpler; modern fully automatic box gluing machines can significantly reduce labor and time costs. In contrast, nail boxes require additional nailing equipment, increasing the investment costs and maintenance difficulties for enterprises.

Market Demand Analysis

1. Product Safety:

- Nail-less Boxes: The market's emphasis on environmental friendliness and aesthetics has made nail-less boxes increasingly popular. The nail-less design reduces the use of metal nails, minimizing the risk of scratching products, making them suitable for high-demand packaging such as precision electronics and food.

- Nail Boxes: For heavy items (such as home appliances and furniture), nail boxes maintain a market share due to their excellent load-bearing capacity and durability. Consumers and businesses tend to prefer nail boxes for transportation and storage when there are high demands for sturdiness.

2. Environmental Considerations:

- Nail Boxes: Due to the use of metal materials, nail boxes generally have certain disadvantages in terms of environmental impact. However, their strong strength makes them irreplaceable for packaging some heavy products. There remains a reasonable demand for nail boxes in the market.

Both nail-less boxes and nail boxes have their own advantages and disadvantages. With the continuous advancement of box gluing machine technology, nail-less boxes are increasingly becoming the new favorite in the market, meeting the demands for environmental friendliness and aesthetics, while nail boxes continue to provide value in terms of load-bearing and sturdiness. When choosing a packaging format, enterprises should consider their target market, product characteristics, and cost-effectiveness comprehensively to make appropriate decisions.