I.Corrugated box equipment overview

Corrugated box equipment refers to machinery used to manufacture, process and finish corrugated board into cartons, packaging and other structural solutions. The corrugated packaging industry relies on specialized machines to provide high-quality, durable and cost-effective packaging solutions for a variety of industries such as food and beverage, e-commerce, electronics and logistics.

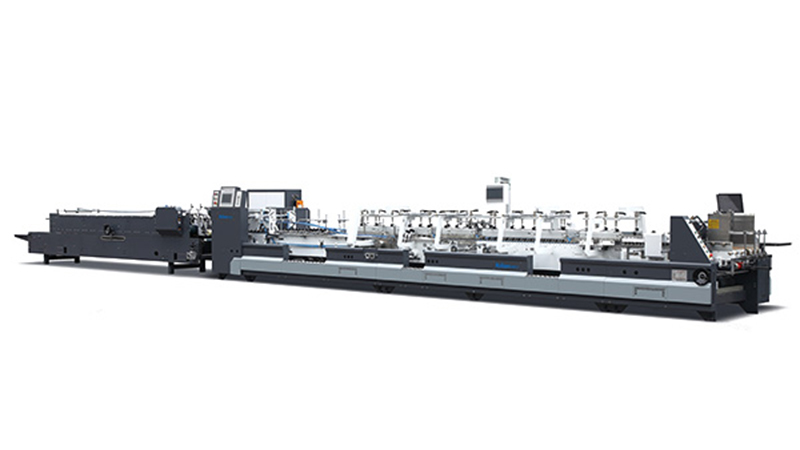

One of the most critical pieces of equipment in corrugated box equipment is the folder gluer, which is designed to efficiently fold and glue corrugated board into finished cartons.

II.What is a folder gluer?

A folder gluer is a high-speed machine that automates the folding and gluing process of corrugated board to convert flat board into completed cartons. This machine is essential for large-scale production and ensures precision, speed and consistency in carton manufacturing.

Key functions of a folder gluer:

1. Fold – The machine creases and folds the corrugated board along pre-scored lines to form a box structure.

2. Gluing – Apply adhesive to necessary seals to ensure a secure seal on the carton.

3. Counting and stacking – Many advanced folder gluers also include counting and stacking features to simplify the packaging and shipping process.

III.Types of Corrugated Folder Gluers

With over 20 years of experience in manufacturing packaging machinery, Rolam specializes in manufacturing various types of folder gluers and has a wide range of folder gluers to meet a variety of production methods under different needs.

1. Straight Folder Gluer

Processes cartons in a straight line configuration.

Suitable for standard cartons and regular slotted cartons (RSC).

High-speed production with minimal setup changes.

2. Bottom-locking Folder Gluer

Specialized for self-locking cartons that do not require tape or glue as the bottom.

Commonly used for retail packaging.

3. Integrated die-cutting and folding/gluing automatic folder gluer

Die-cutting and folding/gluing can be completed in one machine.

Suitable for complex carton designs with custom shapes.

4. 4/6-corner folder gluer

Handles more complex box styles, including four-corner and six-corner designs.

For high-end packaging solutions.

IV.Benefits of using a folder gluer in cardboard box production

Efficiency – produces thousands of boxes per hour.

Consistent quality – ensures uniform folding and gluing of each box.

Reduced labor costs – minimizes manual operations and reliance on labor.

Versatility – adjustable settings for different box styles and sizes.

Reduced waste – precise gluing reduces material waste.

V.Choosing the right folder gluer for your business

When choosing a folder gluer for cardboard box, consider the following factors:

Output – high-speed machines are suitable for large-scale production, semi-automatic machines are suitable for small batches.

Complexity of boxes – linear machines are suitable for simple box production, and multi-functional machines are suitable for complex designs.

Level of automation – fully automatic systems with integrated robots are suitable for smart factories.

Maintenance and support – availability of spare parts and technical services.

Conclusion

Corrugated box folder-gluers are the cornerstone of modern packaging production, enabling companies to meet high demands while maintaining quality and efficiency. Investing in the right corrugated equipment can significantly increase productivity, reduce costs, and improve the overall competitiveness of your packaging business.

Whether you are a corrugated box manufacturer or a business looking to optimize your packaging process, understanding the role of folder-gluers and other corrugated machinery is essential to success in today’s fast-paced market.