Application analysis of box folding and gluing machine

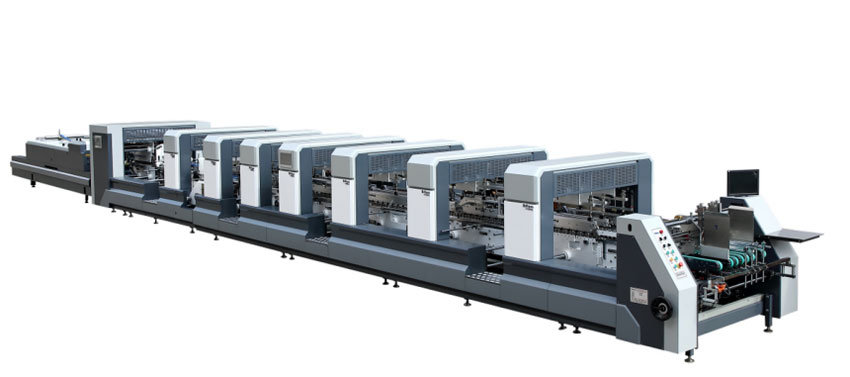

In the packaging and printing industry, the application of the box gluing machine is the last process of packaging box processing, which is to fold the printed and die cut cardboard into shape and glue it. Machine gluing box replaces manual making, which is reducing labor costs and improving efficiency. The box gluing machine is divided into paper feeding section, pre folding section, crash lock bottom, forming section and trombone section.

The working principle of the box gluing machine is that the whole process of automatic input, gluing, folding,gluing flattening and collecting of creased cardboard to realize the sticky box.

In the packaging and printing industry, the gluing machine is one of the important post press processing equipment. At present, with the rapid development of the packaging and printing industry in China, the box gluing machine is more and more widely used. Packaging boxes for food, medicine, health products, cosmetics, alcohol, light industrial products, etc. are basically processed by the box gluing machine.

Current situation of the box pasting machine market:

In 2021, the sales volume of the global box pasting machine market will reach 270 million dollars, and it is expected to reach 390 million dollars in 2028, with a CAGR of 5.4% (2022-2028).

The world's major manufacturers of Folder Gluers include BOBST, Koenig&Bauer Duran, VEGA, etc. The market share of the world's top three manufacturers exceeded 33%.

The Asia Pacific region is the largest market, with a market share of about 36%, followed by North America and Europe, with a market share of about 54%.

Features of the New Rolam box folding and gluing machine

(1) Box type adaptability

Our original carton pasting machine has a single function and can only adapt to one or two general box types. The manufacturers of foreign customers pay special attention to the processing requirements for complex box types. Therefore, we have developed a new carton pasting machine to adapt to more diversified box types, such as hexagonal boxes, octagonal boxes and special-shaped boxes.

(2) Scalability and flexibility

The old pasting machine can only be used as an ordinary straight box or a bottom lock box. If other functions need to be added, it is difficult, and the model structure must be modified. Now we adopt modular design, and users can add corresponding functional modules or components on the gluing machine according to the specific situation of the product, without changing the model structure, which is highly flexible.

(3) Stability

In terms of stability, the current pasting machine has stable performance and low failure rate, greatly improving production efficiency and reducing maintenance costs. The box pasting machine should also win. The failure rate of domestic box pasting machine is high. Therefore, many packaging and printing plants that choose domestic equipment generally have multiple domestic box pasting machines to avoid affecting normal production and delaying delivery due to machine maintenance.

(4) machine working speed

The production speed of the pasting machine can reach 400m/min.

(5) Automation

In terms of the degree of automation, for example, when a product is produced and another box type product is replaced, automatic control is adopted, and specific values can be displayed on the display screen. The latest intelligent box pasting machine also has memory function, which greatly improves the automation and intelligence of production. The higher the degree of automation of the equipment, it means that it can reduce the number of employees and save costs.

(6) Operational aspects

In terms of operability, it is simpler, more humanized and more intelligent.

(7) Service life

The updating and design of the machine greatly extend the trial life of the machine, so that customers can use it with more confidence.

Future development trend of the box folding and gluing machine

1. Versatility and mobility

From the perspective of international market share, linear boxes account for about 60%, bottom lock boxes account for about 30%, hexagonal boxes, octagonal boxes, and special-shaped boxes account for about 10%, and the proportion of linear boxes is declining, while the proportion of special-shaped boxes is gradually increasing. At present, standard straight boxes are still widely used in China's packaging market. With the acceleration of the process of economic globalization and the intensification of market competition, consumers and packaging users have higher and higher requirements for packaging boxes. In order to improve the added value of products, the box type design of packaging boxes has become increasingly diversified, and the demand for some advanced automatic bottom locked color boxes is increasing, including toy boxes, wine boxes, medicine boxes, etc. This complex box type can not be effectively made by manual or simple pasting machine. In terms of box type adaptability, we require more versatility and mobility.

2. High speed and high productivity

As a color box supplier, whether it can provide instant production and instant supply has become a prerequisite for customers to choose. Delivery on time and providing enough cartons or boxes in the shortest time will help to obtain orders. It is required that the gluing machine must be easy to adjust, with high production speed and alos stability, because the manufacturer needs to be ready for production at any time.

3. Adapt to the production of small batch packaging boxes

At present, there are more and more short versions and small batch boxes mainly rely on manual work. If the automatic gluing box machine can make a breakthrough in small batch production in the future, it will be more conducive to the promotion and application of the automatic gluing box machine.

4. Improve automation

At a time when the whole printing industry is developing towards a tighter deadline, shorter operation cycle, more job conversion and the need to reduce the set preparation time, post press equipment manufacturers are also facing increasing pressure. The higher the degree of automation of the automatic folding and gluing machine, the lower the dependence on the operators. At the same time, it can improve the production efficiency and reduce the labor intensity of the operators. The operability will become more and more humanized, reflecting the design concept of "people-oriented".